When it comes to cooling systems, two types of compressors stand out: AC compressors and refrigerator compressors. While both play a crucial role in maintaining comfortable temperatures, they serve different purposes and come with unique characteristics.

In this article, we’ll dive deep into the workings and distinctions of these compressors, providing valuable insights to help you make informed decisions.

AC Compressor Vs. Refrigerator Compressor

AC compressors cool indoor spaces and release heat outside, while refrigerator compressors cool food and release heat to the ambient air or water loop. Both serve different purposes in cooling systems.

Here is a comparison chart for AC compressor vs. refrigerator compressor:

| AC Compressor | Refrigerator Compressor |

|---|---|

| Designed specifically for air conditioning systems | Designed for cooling, heating, and ventilation systems |

| Raises the pressure of atmospheric air to a desired level | Raises the pressure of refrigerant gas to a high level |

| Compressed air is used to do work downstream and then released to the atmosphere | Compressed refrigerant is used to remove heat from inside air and then recaptured and reused |

| Can use different types of compressors, such as reciprocating, rotary, and axial | Usually uses reciprocating or rotary compressors |

| Lubricant selection is relatively simple | Lubricant selection depends on the type of refrigerant used |

| May have multiple stages of compression and cooling | Has a single stage of compression and condensation |

| Operates at higher temperatures than refrigerator compressors | Operates at lower temperatures than AC compressors |

Function

AC compressors play a vital role in the comfort of indoor spaces.

They are the heart of air conditioning systems and heat pumps, responsible for cooling the air during warm weather and heating it in colder conditions.

The process starts when the AC compressor receives low-pressure, low-temperature refrigerant gas from the evaporator.

It then compresses the gas, raising its pressure and temperature significantly. The hot, high-pressure refrigerant gas is then sent to the condenser, where it releases heat to the outside air.

The cooled refrigerant then expands back to a low-pressure, low-temperature state in the evaporator, and the cycle repeats.

On the other hand, refrigerator compressors operate in a similar manner but serve a different purpose.

They are essential components of refrigeration systems found in fridges, freezers, ice makers, and even vending machines.

The refrigerator compressor receives low-pressure, low-temperature refrigerant gas from the evaporator inside the appliance.

It then compresses the gas, raising its pressure and temperature, just like an AC compressor.

However, instead of releasing the heat to the outside air, the refrigerator compressor has options: it can either release the heat to the ambient air surrounding the appliance or transfer it through a water loop (commonly used in large commercial refrigerators).

Application

AC compressors are versatile and widely used in various applications. They play a crucial role in cooling indoor spaces in residential buildings, commercial establishments, vehicles, and even aircraft.

Beyond cooling, AC compressors are also used in heating systems, acting as the heart of heat pumps that extract heat from the outside air and transfer it indoors during colder months.

On the other hand, refrigerator compressors are specialized for cooling and preserving perishable items, primarily food and beverages.

You can find refrigerator compressors in refrigerators, freezers, and ice makers used in both domestic and commercial settings.

These compressors work to maintain the temperature inside the refrigerator or freezer at a level suitable for preserving the freshness and quality of food.

Types

The design and technology of compressors are diverse, leading to several types catering to different applications. In the world of AC compressors, you will find various types, including:

- Reciprocating Compressors: These use a piston-cylinder mechanism to compress the refrigerant gas. They are commonly found in small to medium-sized residential and commercial AC units.

- Rotary Compressors: These compressors use rotating blades or vanes to compress the refrigerant. They are popular for their compact size and smooth operation, making them suitable for portable AC units and small cooling systems.

- Scroll Compressors: Scroll compressors use two spiral-shaped scrolls that interlock to compress the refrigerant gas. They are known for their high efficiency and quiet operation, making them ideal for residential and commercial air conditioning systems.

- Screw Compressors: Screw compressors utilize two helical rotors to compress the refrigerant gas. They are commonly found in large industrial air conditioning systems.

- Centrifugal Compressors: These compressors use a rotating impeller to accelerate the refrigerant gas and increase its pressure. They are typically used in large commercial and industrial HVAC systems.

Similarly, refrigerator compressors also come in different types, such as:

- Reciprocating Compressors: Similar to those used in AC systems, reciprocating compressors are commonly found in household refrigerators and small commercial units.

- Rotary Compressors: These compact compressors are widely used in domestic refrigerators and freezers.

- Scroll Compressors: In some cases, scroll compressors are also utilized in larger refrigeration systems due to their efficiency and quiet operation.

- Linear Compressors: These advanced compressors use a linear motor to drive the piston, providing improved efficiency and precise temperature control. They are commonly found in high-end refrigeration appliances.

Refrigerant

Both AC compressors and refrigerator compressors rely on refrigerants to carry out the cooling process.

Refrigerants are chemicals with unique thermodynamic properties that enable them to change states between gas and liquid at specific temperatures and pressures, making them ideal for heat transfer.

In the realm of AC compressors, various refrigerants have been used over the years, and advancements continue to be made for improved performance and environmental friendliness.

Some common refrigerants include R-22 (chlorodifluoromethane), R-410A (hydrofluorocarbon), R-134a (tetrafluoroethane), R-32 (difluoromethane), and R-290 (propane).

Each refrigerant has its advantages and disadvantages, with considerations for factors like energy efficiency, global warming potential (GWP), ozone depletion potential (ODP), and safety.

Similarly, refrigerator compressors also rely on specific refrigerants to achieve optimal cooling performance while maintaining safety and environmental considerations.

Common refrigerants used in refrigerators include R-134a (1,1,1,2-tetrafluoroethane), R-600a (isobutane), R-290 (propane), and R-744 (carbon dioxide).

Manufacturers often select refrigerants based on their environmental impact, energy efficiency, and compatibility with the system.

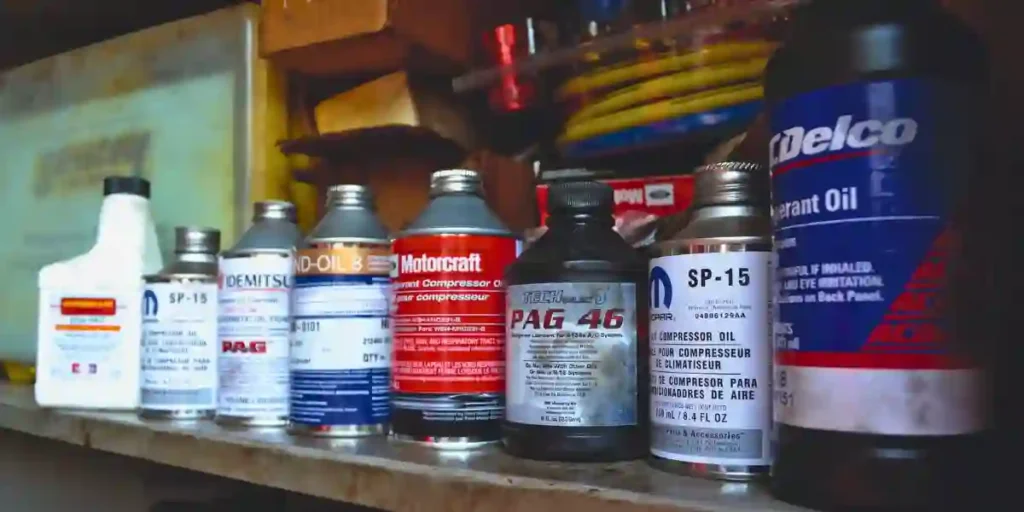

Lubricant

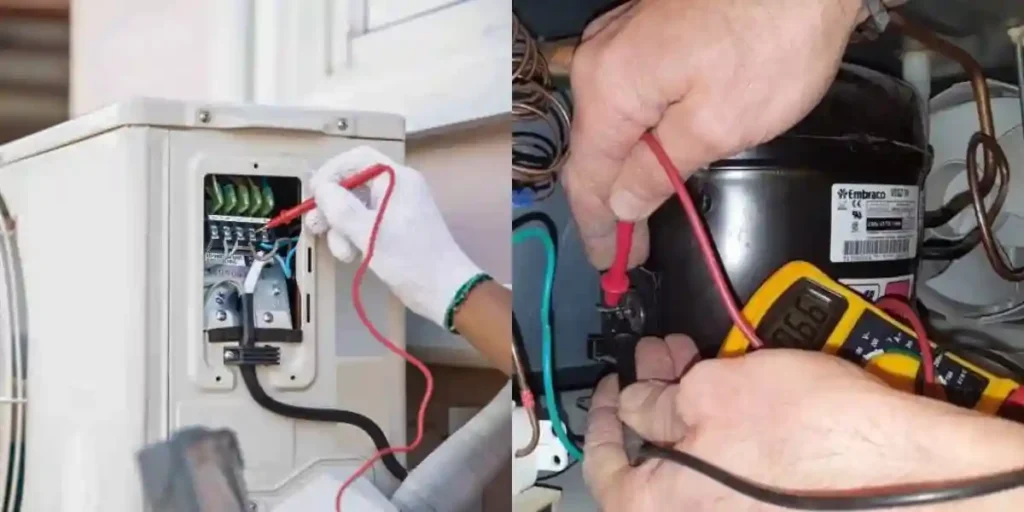

Both AC compressors and refrigerator compressors require lubrication to ensure smooth operation and prevent wear and tear on moving parts.

In AC compressors, the lubricant must be compatible with the specific type of refrigerant used in the system.

It should have good thermal stability to handle the heat generated during compression and a low volatility rate to prevent loss through evaporation.

Additionally, the lubricant should possess a high viscosity index to maintain its lubricating properties across a range of operating temperatures.

On the other hand, refrigerator compressors demand lubricants with unique characteristics.

These lubricants must be compatible with the refrigerant used in the system and should have good chemical stability to prevent breakdown when exposed to the refrigerant.

Moreover, they should have a low pour point to remain effective in low-temperature environments typically found in refrigerators and freezers.

Additionally, lubricants with high solubility are preferred to ensure efficient circulation throughout the refrigeration system.

Power Consumption

AC compressors and refrigerator compressors differ significantly in power consumption due to their distinct cooling requirements.

AC compressors need to handle larger cooling loads as they are responsible for cooling entire indoor spaces.

In contrast, refrigerator compressors only need to maintain the temperature within a confined refrigerated space.

As a result, AC compressors consume more power due to their longer running times and higher cooling capacities.

On the other hand, refrigerator compressors operate intermittently, cycling on and off as needed to maintain the desired temperature.

This intermittent operation, along with the smaller cooling load, contributes to lower power consumption in refrigerator compressors.

Cost & Efficiency

The cost and efficiency of AC compressors and refrigerator compressors are closely related to their design, size, and capacity.

AC compressors are generally more expensive due to their larger size and higher complexity.

They need to handle larger volumes of air and provide precise temperature control in various applications, which often require more advanced technology.

Refrigerator compressors, being smaller and less complex, are more cost-effective. Their capacity is sufficient to cool the confined space inside refrigerators and freezers without the need for extensive cooling capabilities.

Additionally, refrigerator compressors are known for their higher energy efficiency compared to AC compressors.

Since they operate in smaller spaces and for shorter durations, they consume less energy while maintaining the desired temperature.

Noise & Maintenance

Noise levels and maintenance requirements are crucial considerations when choosing between AC compressors and refrigerator compressors.

AC compressors typically generate more noise during operation due to their higher rotational speeds and increased vibration caused by larger cooling loads.

The noise can be a concern, especially in residential settings where quiet operation is essential.

On the other hand, refrigerator compressors are designed for quieter operation. Their smaller size and lower cooling loads result in reduced noise levels, making them suitable for household environments where noise disruption is undesirable.

In terms of maintenance, AC compressors demand more attention due to the higher wear and tear they experience.

The constant cooling and heating cycles, along with the higher pressure and temperature, can put more strain on the components, necessitating regular maintenance to ensure peak performance.

Refrigerator compressors, operating under milder conditions, require less frequent maintenance.

However, it is still essential to conduct regular maintenance checks to ensure their optimal performance and prolong their life span.

Reliability & Life Span

The reliability and life span of AC compressors and refrigerator compressors are closely related to their design, usage, and maintenance. AC compressors, with their

higher operating stress and load, are generally considered less reliable and have a shorter life span compared to refrigerator compressors.

Refrigerator compressors, operating in smaller and less demanding cooling systems, experience lower stress and load, resulting in greater reliability and a longer life span.

Regular maintenance further contributes to their durability and extends their operational life.

Environmental Impact & Safety

The environmental impact and safety considerations of AC compressors and refrigerator compressors are of utmost importance.

AC compressors, especially in older systems that use certain refrigerants like R-22, can have a significant environmental impact due to their contribution to ozone depletion and global warming.

However, advancements in refrigerant technology have led to the use of more environmentally friendly options like R-410A and R-32, which have lower ozone depletion potential and global warming potential.

On the other hand, refrigerator compressors are relatively more environmentally friendly. They typically use refrigerants like R-600a and R-290, which have minimal impact on ozone depletion and significantly lower global warming potential.

The use of such refrigerants helps reduce the overall environmental footprint of refrigerator systems.

Safety is also a vital consideration when it comes to refrigeration systems. AC compressors, especially those using certain older refrigerants, may pose safety risks in case of leakage or mishandling.

Refrigerator compressors, with their use of safer refrigerants, present lower safety risks, making them more suitable for household use.

Regulation

Due to their significant environmental impact, AC compressors are subject to stricter regulations regarding refrigerant usage and emissions.

Authorities enforce higher environmental standards and energy efficiency requirements to promote the use of more environmentally friendly refrigerants and technology.

In contrast, refrigerator compressors, which have a relatively lower environmental impact, are subject to less stringent regulations.

While they still need to adhere to safety standards and performance requirements, the regulations for refrigeration systems are generally not as strict as those for large-scale AC systems.

Choosing the Right Compressor for Your Needs

1. Understand Your Application Requirements

Before diving into the world of compressors, start by understanding your specific application requirements.

Consider factors such as the type of equipment or system you need the compressor for, the required cooling capacity, and any other specific needs unique to your application.

2. Explore Different Compressor Types

Next, familiarize yourself with the various types of compressors available. Common types include reciprocating, rotary, scroll, screw, and centrifugal compressors.

Each type has its advantages and limitations, so understanding their operating principles and applications will help you make an informed choice.

3. Evaluate Environmental Impact

In today’s environmentally conscious world, it’s crucial to consider the environmental impact of the compressor’s refrigerant.

Opt for refrigerants with low global warming potential (GWP) and ozone depletion potential (ODP) to minimize your carbon footprint and contribute to a greener future.

4. Assess Energy Efficiency

Energy efficiency is another critical aspect to consider. Compressors with higher coefficient of performance (COP) are more energy-efficient, helping you save on operating costs while reducing energy consumption.

5. Check Noise Levels

For applications where noise is a concern, look for compressors with lower operational noise levels.

Scroll compressors, for example, are known for their quiet operation, making them ideal for noise-sensitive environments.

6. Consider Maintenance Requirements

Maintenance is an essential aspect of compressor ownership. Consider the maintenance requirements of different compressor types, and choose one that aligns with your maintenance capabilities and schedule.

7. Budget and Cost

Last but not least, consider your budget and overall cost. While high-quality compressors may come with a higher initial cost, their energy efficiency and reliability can lead to long-term cost savings.

FAQs

Can I use an AC compressor in a refrigerator?

No, AC compressors and refrigerator compressors have different designs and are optimized for different cooling requirements. Using an AC compressor in a refrigerator would likely lead to inefficient cooling and potential damage to the system.

Is a refrigerator compressor more energy-efficient than an AC compressor?

Yes, in general, refrigerator compressors are more energy-efficient due to their smaller cooling load and shorter running times compared to AC compressors, which handle larger cooling loads in continuous operation.

Can I replace the refrigerant in my AC compressor with a more eco-friendly option?

In some cases, it is possible to retrofit older AC systems with more environmentally friendly refrigerants. However, this process requires professional expertise to ensure compatibility and safety.

How often should I maintain my AC compressor and refrigerator compressor?

Regular maintenance is essential for both AC and refrigerator compressors to ensure optimal performance and prolong their life span. AC compressors typically require more frequent maintenance due to their higher operating stress.

Conclusion

Understanding the differences between AC compressors and refrigerator compressors is crucial for choosing the right cooling system for specific applications.

While AC compressors are ideal for cooling indoor spaces, refrigerator compressors excel in preserving food and maintaining low temperatures.

The choice of refrigerant and compressor type plays a significant role in determining energy efficiency, environmental impact, and overall performance.

Whether it’s cooling your home or preserving food, knowing the nuances of these compressors empowers you to make informed decisions for your specific cooling needs.

Resources:

1. https://www.globalspec.com/learnmore/building_construction/hvac/ventilation/refrigeration_compressors_air_conditioning_compressors

2.