If you run a commercial kitchen or food service business, you know how crucial it is to keep your walk-in cooler working efficiently.

If you’ve noticed that the compressor keeps turning on and off frequently, you may be concerned about the energy bills and the equipment’s lifespan.

This blog post will explore why this happens and what you can do to fix it.

Why Your Walk-In Cooler Compressor Keeps Turning On and Off

If your walk–in cooler compressor keeps turning on and off, it could be due to several reasons.

Insufficient cooling load

A compressor turns on and off to maintain the set temperature inside a walk-in cooler.

If the cooling load is too low, the cooler may reach the set temperature quickly, causing the compressor to cycle frequently.

Possible causes of a low cooling load include an oversized cooler, a small inventory, an inefficient door seal, or an inaccurate thermostat.

You may need to adjust the thermostat or upgrade the cooler’s insulation or door gasket.

Dirty condenser coils

The condenser coils of a refrigeration system release the heat absorbed by the evaporator coils.

If the condenser coils are dirty or blocked, they may not dissipate heat effectively, causing the compressor to overheat and shut down.

To clean the condenser coils, you can use a soft brush, compressed air, or a coil cleaning solution.

Make sure to turn off the power to the compressor and follow the manufacturer’s instructions to avoid damaging the coils or the refrigerant.

Low refrigerant charge

The refrigerant in a cooling system absorbs heat when it evaporates and releases heat when it condenses.

If the refrigerant charge is low, the evaporator coils may not absorb enough heat, causing the compressor to cycle frequently or run continuously.

Low refrigerant charge can result from a leak, a poor installation, or a refrigerant overcharge or undercharge.

To diagnose and fix a refrigerant issue, you may need to hire a licensed refrigeration technician who can use specialized tools and equipment.

Faulty or worn-out components

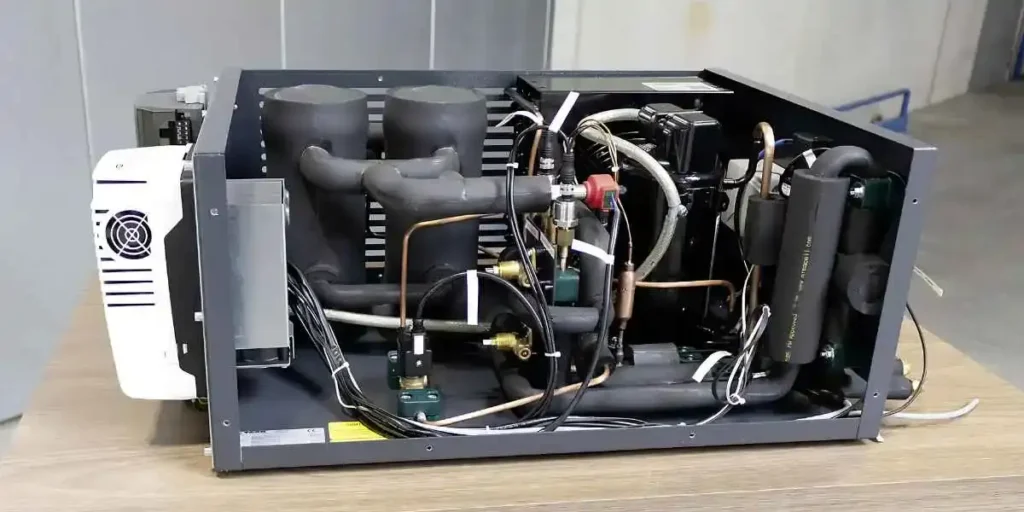

A refrigeration system consists of various components, such as the compressor, the fan motor, the pressure switches, the relays, the capacitors, and the contractors.

If any of these components fail or malfunction, the compressor may not start, stop, or operate properly, causing the cooler to lose cooling capacity or efficiency.

Common signs of faulty or worn–out components include unusual noises, voltage drops, high amperage draws, or erratic temperature readings.

To replace or repair a faulty component, you may need to order a replacement part or consult a refrigeration technician who can troubleshoot the problem and suggest a solution.

Inadequate ventilation or airflow

A compressor needs sufficient ventilation and airflow to dissipate heat and prevent overheating.

If the compressor is located in a tight or enclosed space, or if the air intake or exhaust is obstructed or restricted, the compressor may overheat and cycle frequently or shut down.

To improve the ventilation or airflow, you can install fans, ducts, or louvers, or relocate the compressor to a more suitable location.

Make sure to follow the local codes and regulations and consult a licensed technician or engineer if necessary.

The Benefits of Advanced Compressor Control Systems

Here are some ways that these systems can improve your operations and bottom line.

Energy savings

By optimizing the compressor’s operation and adjusting it to the actual cooling demand, advanced control systems can reduce the energy consumption of the refrigeration system.

This can lead to lower electricity bills, reduced carbon footprint, and improved sustainability.

Reduced wear and tear

Advanced control systems can also prolong the lifespan of the compressor and other components by minimizing unnecessary cycling, load fluctuations, and thermal stresses.

This can result in lower maintenance costs, less downtime, and greater reliability.

Improved system stability

By maintaining a more stable and consistent temperature and pressure, advanced control systems can prevent sudden temperature changes, frost buildup, and other issues that can affect the quality and safety of refrigerated products.

This can also help you comply with regulatory requirements and customer expectations.

Enhanced monitoring and diagnostics

Advanced control systems can provide real-time monitoring, data logging, and remote access to the system’s performance and status.

This can help you identify and troubleshoot issues faster, make informed decisions about maintenance and repairs, and optimize the system’s operation over time.

Customizable settings and alerts

Advanced control systems can allow you to customize the settings, alarms, and notifications based on your specific needs and preferences.

This can help you respond to changing conditions, prevent critical failures, and ensure the system operates at its peak efficiency and effectiveness.

Common Problems with Compressor Cycling

Here are some common problems associated with compressor cycling.

Short cycling

Short cycling occurs when the compressor turns on and off too frequently, typically less than 5 minutes apart.

This can lead to increased wear and tear on the compressor and other components, reduced energy efficiency, and poor temperature control.

Thermal stress

Compressor cycling can also cause thermal stress on the compressor, which can lead to premature failure and reduced reliability.

This is particularly true when the compressor is exposed to wide temperature swings and rapid load changes.

Low refrigerant charge

Compressor cycling can also be a symptom of a low refrigerant charge, which can lead to poor cooling performance, increased energy consumption, and compressor overheating.

If the refrigerant level is low, it is important to address the root cause and recharge the system as soon as possible.

Electrical issues

Compressor cycling can also be caused by electrical problems, such as a faulty pressure switch, relay, or thermostat.

These issues can affect the compressor’s operation and lead to excessive cycling, reduced efficiency, and potential safety hazards.

Contaminants in the system

Compressor cycling can also be caused by contaminants in the refrigeration system, such as moisture, oil, or dirt.

These contaminants can affect the pressure and temperature of the system, leading to erratic operation and increased cycling.

How to Troubleshoot Compressor Cycling Issues

If your compressor keeps cycling on and off frequently, it could be due to several reasons.

Check the thermostat

Ensure that the thermostat is set to the correct temperature and functioning properly.

If the thermostat is faulty, it may be sending incorrect signals to the compressor to turn on and off.

Check the refrigerant levels

Low refrigerant levels can cause the compressor to cycle frequently, as it struggles to maintain the desired temperature.

Check the refrigerant levels and add more if necessary. If the refrigerant is low, it may also indicate a leak in the system that needs to be repaired.

Inspect the condenser coil

A dirty or clogged condenser coil can restrict the airflow and cause the compressor to cycle more often. Inspect the coil and clean it if necessary.

Check the evaporator coil

A frozen evaporator coil can cause the compressor to cycle frequently. Check the coil and defrost it if necessary.

Check the compressor relay

A faulty compressor relay can cause the compressor to cycle more often than necessary. Test the relay and replace it if it’s defective.

Check the compressor motor

If the compressor motor is faulty or worn out, it may cause the compressor to cycle more frequently. Test the motor and replace it if necessary.

Check the electrical connections

Loose or corroded electrical connections can cause intermittent signals to the compressor, resulting in cycling issues.

Inspect the connections and tighten or clean them if necessary.

Maintenance Tips for Efficient Compressor Cycling

Efficient compressor cycling is essential for maintaining optimal performance and extending the lifespan of your refrigeration system. Here are some tips to keep your compressor cycling efficiently:

Clean the condenser coils

Dirty condenser coils can reduce the efficiency of the refrigeration system, increase the workload on the compressor, and lead to more frequent cycling.

Clean the coils regularly to remove dirt, dust, and debris that can obstruct the airflow and hinder heat transfer.

Check the refrigerant level

Low refrigerant levels can cause the compressor to run longer and more frequently, leading to higher energy consumption and premature wear and tear.

Check the refrigerant level regularly and add more if needed.

However, make sure to follow the manufacturer’s guidelines and regulations for refrigerant handling.

Inspect the compressor oil

The compressor oil lubricates and cools the compressor’s moving parts, preventing excessive wear and overheating. Check the oil level and condition regularly and replace or top it up as necessary.

Use the recommended type and grade of oil for your compressor and climate conditions.

Monitor the suction and discharge pressure

The suction and discharge pressure can indicate if the compressor is working efficiently and if there are any issues with the refrigeration system.

Monitor the pressure regularly and compare it with the recommended values for your specific system and application.

If the pressure is too low or too high, it may indicate a refrigerant leak, clogged filter, or other problem that needs to be addressed.

Schedule preventive maintenance

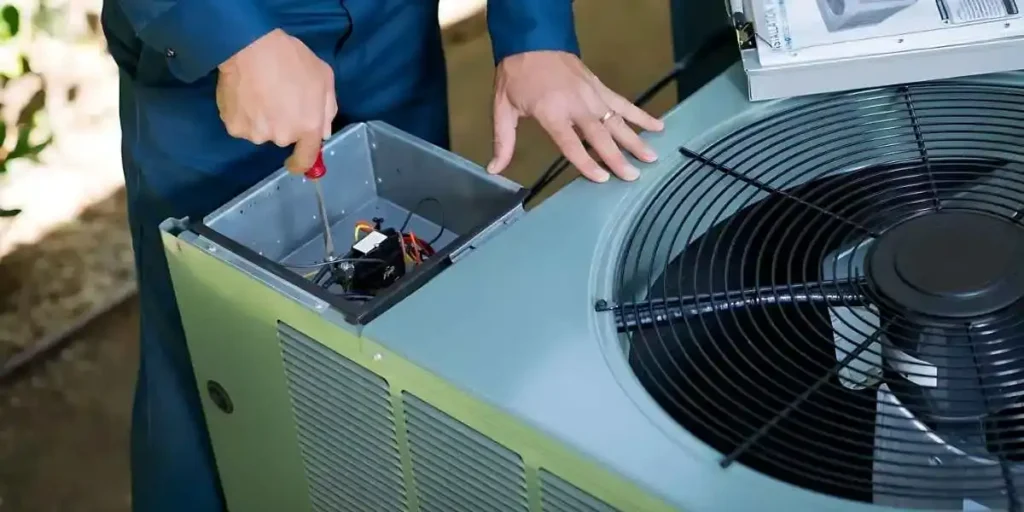

Regular preventive maintenance can help you detect and fix minor issues before they turn into major problems that can cause compressor failure or system breakdown.

Schedule annual or bi-annual inspections and tune-ups with a qualified refrigeration technician who can inspect, clean, and test all components of the system, including the compressor.

FAQS

Can A Dirty Condenser Coil Cause The Compressor To Cycle On And Off Frequently?

Yes, a dirty condenser coil can reduce the efficiency of the refrigeration system, increase the workload on the compressor, and cause it to cycle on and off more frequently. Cleaning the condenser coil regularly can help prevent this issue.

Can A Low Refrigerant Level Cause The Compressor To Cycle On And Off Frequently?

Yes, a low refrigerant level can cause the compressor to run longer and more frequently, leading to higher energy consumption and premature wear and tear. Checking and maintaining the proper refrigerant level can help prevent this issue.

Can A Faulty Thermostat Cause The Compressor To Cycle On And Off Frequently?

Yes, a faulty thermostat can cause the compressor to turn on and off more frequently than necessary. Replacing or adjusting the thermostat may be necessary to resolve this issue.

How Often Should I Schedule Preventive Maintenance For My Walk-In Cooler?

It’s recommended to schedule preventive maintenance at least once a year or bi-annually to ensure optimal performance, detect minor issues early, and prolong the lifespan of the refrigeration system.

Can I Perform Maintenance On My Walk-In Cooler Compressor Myself?

It’s not recommended to perform maintenance on the compressor yourself unless you’re a qualified refrigeration technician with the necessary skills, knowledge, and tools. Attempting to repair or modify the compressor without proper training can be dangerous and cause further damage to the system.

Conclusion

Maintaining the optimal performance of your walk-in cooler requires regular preventive maintenance, including cleaning the condenser coil, checking refrigerant levels, and inspecting the compressor, thermostat, and other components.

Consulting a qualified refrigeration technician to diagnose and resolve any issues promptly can help avoid costly repairs and downtime.