How Ice Makers Use Sensors to Stop Filling? Sensor Insights

We may earn affiliate fees for purchases using our links (at no additional cost to you).

Ice makers have become a common household and commercial appliance, but overfilling can cause damage and waste resources.

To prevent these issues, ice makers now use sensor technology that stops filling once the ice bin is full.

This blog will explore how sensors regulate water filling in ice makers, the benefits of this technology, and the latest developments in ice maker sensor technology.

How Ice Makers Use Sensors to Regulate Water Filling

Ice makers may seem like simple appliances, but behind their operation lies a complex system of sensors and mechanisms.

Water Level Sensor

The water level sensor is one of the key sensors used in ice makers. This sensor is typically located in the ice maker’s reservoir and is designed to detect the water level.

When the water level drops below a certain threshold, the sensor sends a signal to the ice maker’s control board, which then activates the water fill valve.

Water Fill Valve

The water fill valve is responsible for regulating the flow of water into the ice maker’s reservoir.

This valve is controlled by the ice maker’s control board, which receives input from the water level sensor.

When the water level drops below the threshold, the control board activates the water fill valve to fill the reservoir with water.

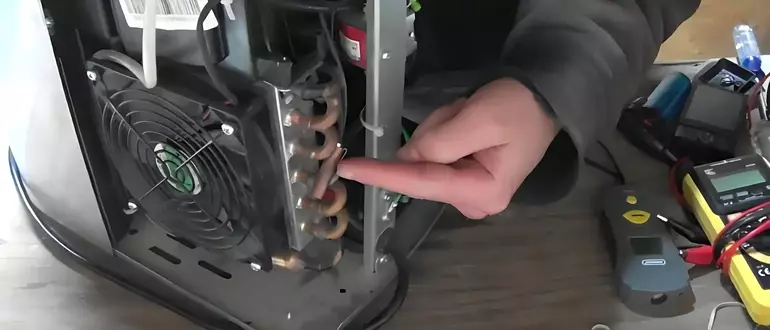

Ice Thickness Sensor

Ice makers also use an ice thickness sensor. This sensor is located near the evaporator plate and is designed to measure the thickness of the ice.

When the ice reaches a certain thickness, the sensor sends a signal to the ice maker’s control board, which then turns off the water fill valve and activates the harvest cycle.

Harvest Cycle

The harvest cycle is the final stage in the ice-making process. During this cycle, the ice makers evaporator plate is heated, which causes the ice to loosen and fall into the ice bin.

The harvest cycle is initiated by the ice thickness sensor and is controlled by the ice maker’s control board.

The Benefits of Sensor-Enabled Ice Makers

Traditional ice makers are being replaced by sensor-enabled ones, offering a range of benefits for businesses.

Improved Food Safety

Sensor-enabled ice makers can improve food safety by reducing the risk of contamination.

The sensors can detect when the ice levels are low or when the ice is contaminated, triggering an alert to notify maintenance personnel to clean the machine.

The ice produced should be free from harmful bacteria, providing a safer environment for food service establishments.

Energy Efficiency

Sensor-enabled ice makers are designed to use less energy, making them more energy-efficient than traditional ice makers.

They can automatically adjust the production rate of ice to meet the demands of the establishment, reducing energy consumption and lowering utility bills.

Increased Productivity

Sensor-enabled ice makers can increase productivity by reducing the need for manual monitoring and maintenance.

They can detect when ice levels are low and produce ice accordingly, eliminating the need for manual ice level checks.

This frees up staff time to focus on other tasks, ultimately increasing the overall productivity of the establishment.

Cost Savings

Sensor-enabled ice makers can save costs in a number of ways. By using less energy, they can reduce utility bills.

Additionally, by detecting and alerting staff to potential maintenance issues early, they can prevent costly breakdowns and extend the lifespan of the machine.

Improved Customer Satisfaction

Sensor-enabled ice makers can also improve customer satisfaction by providing a consistent supply of clean, high-quality ice.

This can enhance the overall experience of customers, whether they are dining in a restaurant or staying at a hotel.

Common Types of Ice Maker Sensors

The modern ice maker is a marvel of engineering, with a variety of sensors that work together to produce clean, high–quality ice.

Bin Level Sensors

Bin level sensors are one of the most common types of sensors found in ice makers.

These sensors detect the level of ice in the bin and can alert staff when the bin needs to be emptied or when the ice level is low.

Water Level Sensors

Water level sensors monitor the level of water in the ice maker, ensuring that the machine always has enough water to produce ice.

If the water level drops too low, the sensor can trigger an alert to notify staff to refill the machine.

Temperature Sensors

Temperature sensors are used to monitor the temperature of the ice maker and ensure that it is operating within the appropriate range.

If the temperature goes outside of the specified range, the sensor can trigger an alert to notify staff of a potential issue.

Ice Quality Sensors

Ice quality sensors are used to ensure that the ice being produced is of high quality and free from contaminants.

These sensors can detect impurities in the ice and trigger an alert to notify staff of a potential issue.

Filter Status Sensors

Filter status sensors monitor the status of the machine’s water filter and can alert staff when the filter needs to be changed. The ice produced by the machine should be clean and free from impurities.

How to Troubleshoot Sensor Issues in Ice Makers

When ice maker sensors malfunction, it can cause a range of issues, from reduced efficiency to poor quality ice.

Check for Obstructions

The first step in troubleshooting sensor issues is to check for any obstructions that may be blocking the sensors.

This could include ice buildup, debris, or other objects that may be interfering with the sensor’s operation.

Clean the Sensors

If there are no obstructions present, the next step is to clean the sensors. Use a soft cloth or brush to gently remove any dirt or debris from the sensors, being careful not to damage them in the process.

Check the Wiring

If cleaning the sensors does not resolve the issue, check the wiring to ensure that it is properly connected and not damaged.

Loose or damaged wiring can cause sensor issues, so it’s important to ensure that all connections are secure and in good condition.

Calibrate the Sensors

The sensors may need to be calibrated in order to function properly. Check the manufacturer’s instructions for your specific ice maker to determine the proper calibration process.

Replace the Sensors

Contact the manufacturer or a qualified technician to determine the appropriate replacement sensors for your ice maker.

Maintenance Tips for Ice Maker Sensors

Follow some of these maintenance tips for Ice maker sensors:

Keep the Sensors Clean

Regular cleaning is one of the most important things you can do to maintain the performance of your ice maker sensors.

Use a soft cloth or brush to gently remove any dirt or debris from the sensors, being careful not to damage them in the process.

Check for Obstructions

Check the sensors regularly to ensure that there are no obstructions blocking their operation.

This could include ice buildup, debris, or other objects that may be interfering with the sensor’s operation.

Test the Sensors

Regularly testing the sensors is an important part of maintaining their performance.

Follow the manufacturer’s instructions to test the sensors and ensure that they are functioning properly.

Calibrate the Sensors

The sensors need to be calibrated in order to function properly. Check the manufacturer’s instructions for your specific ice maker to determine the proper calibration process and schedule regular calibrations as needed.

Replace the Sensors

If the sensors become damaged or stop working properly, it may be necessary to replace them. Contact the manufacturer or a qualified technician to determine the appropriate replacement sensors for your ice maker.

Schedule Regular Maintenance

Regular maintenance is essential for long-term performance and reliability of your ice maker sensors. Schedule regular maintenance with a qualified technician to keep your ice maker operating at peak performance.

Latest Innovations in Ice Maker Sensor Technology

Here are some of the latest innovations in ice maker sensor technology.

Internet of Things (IoT) Integration

Ice makers are now being equipped with IoT technology, allowing businesses to monitor and control their ice makers remotely.

This technology also enables predictive maintenance, helping to identify and address potential issues before they become major problems.

Advanced Water Quality Sensors

Water quality sensors are becoming more sophisticated, with advanced technology that can detect and analyze a wide range of water quality parameters, including pH,

total dissolved solids (TDS), and more. This allows ice makers to produce ice of the highest quality and purity.

Artificial Intelligence (AI) Integration

AI technology is being integrated into ice maker sensors, enabling the machines to learn from user behavior and adjust their operation accordingly.

This can lead to more efficient and effective operation, as well as improved performance over time.

Self-Cleaning Sensors

Self-cleaning sensors are becoming more common in ice makers, helping to reduce the need for manual cleaning and maintenance.

These sensors use advanced technology to automatically clean themselves, ensuring optimal performance and reliability.

Wireless Connectivity

Many ice maker sensors now feature wireless connectivity, allowing for real-time monitoring and control of the machine from a remote location.

This technology also enables the use of mobile apps and other software to provide users with greater control and flexibility.

FAQS

How Do Ice Makers Use Sensors To Stop Filling?

What Happens If An Ice Maker’s Sensor Malfunctions And Doesn’t Stop Filling?

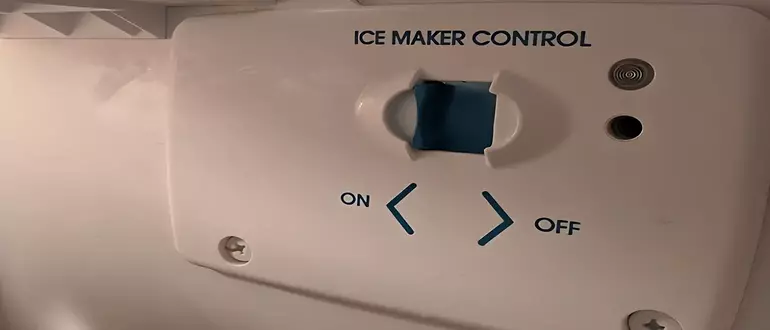

Can Ice Makers Be Manually Stopped From Filling Without Using Sensors?

Conclusion:

The use of sensors in ice makers is crucial for ensuring efficient and safe ice production. By monitoring water levels and other variables, ice makers can prevent overfilling, improve ice quality, and increase reliability.

Regular maintenance and troubleshooting of sensor issues can help ensure that ice makers continue to operate effectively and efficiently.

As sensor technology continues to evolve, we can expect even greater advancements in the ice making industry.